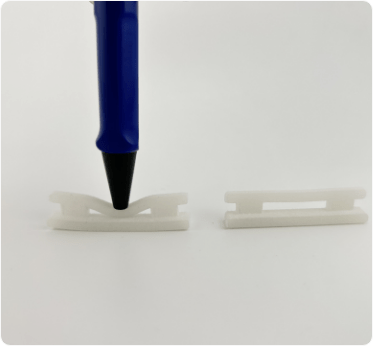

TPU (Thermoplastic Polyurethane) and PLA (Polylactic Acid) are popular 3D printing materials with distinct properties. TPU is known for its exceptional flexibility, elasticity, and durability, making it ideal for objects that require bending or stretching. In contrast, PLA is rigid and brittle, better suited for stable, non-flexible items. PLA is also biodegradable and easier to print with, often chosen for its environmental friendliness and simplicity. TPU's flexibility, however, makes it the go-to choice for parts needing to withstand stress without breaking, like phone cases or wearable items.