Learn about the different types of metal 3D printing and their unique processes. From laser-based methods to powder extrusion, explore the diverse techniques shaping the future of metal additive manufacturing.

Exploring Metal 3D Printing: Various Techniques and Applications

Metal 3D printing, a subset of additive manufacturing, harnesses the strength and durability of metal. Despite the challenges posed by handling raw metal powder, its unique properties make it indispensable. Utilizing methods such as high-energy lasers or extrusion, metal powder is fused into solid metal parts. This article explores the diverse landscape of metal 3D printing technologies, elucidating their processes and underscoring their significance in achieving robust and durable components for various industrial applications.

Metal Powder Bed Fusion

Metal Powder Bed Fusion (PBF) is a cutting-edge additive manufacturing technique widely used in metal 3D printing. It involves spreading a fine layer of metal powder over a build plate and selectively melting it using either a high-powered laser or an electron beam. This process encompasses techniques like Selective Laser Melting (SLM) and Electron Beam Melting (EBM).

PBF in metal 3D printing offers various advantages. It excels in fabricating complex geometries with precision and supports a wide range of metals, including tough ones like titanium alloys and nickel superalloys. Parts made with PBF boast mechanical properties similar to or better than forged metals, ensuring durability. They can also undergo machining, coating, and treatment like conventionally manufactured metal components. PBF provides built-in support from the powder bed, eliminating the need for additional structures and yielding smoother surfaces. With a minimum layer thickness of 20 µm (commonly 35–50 µm), PBF allows for precise detailing and can build more-porous parts when necessary.

PBF comes in different types, named based on the heat source and material used. The main ones are laser beam (PBF-LB) and electron beam (PBF-EB), each with their own unique technologies. Each type has its own pros and cons, so it's important to consider which one is best for your specific application. Some examples include:

1. Selective Laser Sintering (SLS)

SLS, known as Selective Laser Sintering, is a trademarked method falling under PBF-LB. It commonly involves sintering powdered polymer materials like nylon and polyetherketoneketone (PEKK).

2. Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a subtype of PBF-LB where a laser precisely melts metal powder layers together, creating intricate and precise parts with exceptional mechanical properties. Unlike SLS, where powder is sintered, SLM fully melts the powder. This process is commonly used with metals like aluminum alloys, titanium, and stainless steel. Exotic metals like tungsten can also be processed, albeit less frequently. To prevent oxidation and nitriding, an inert atmosphere, typically argon, is maintained in the build chamber. SLM is renowned for its ability to fabricate complex geometries with high accuracy and detail.

3. Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is a similar process to SLM, but it uses an electron gun instead of a laser (thus falling under PBF-EB). The build chamber operates in a vacuum rather than an inert atmosphere, although a small amount of inert gas (usually helium) is used for better process control. EBM can produce parts with comparable strength to SLM but at a faster rate, especially for larger components. Both techniques have distinct advantages, but they require specialized equipment, trained operators, and strict post-processing procedures to ensure quality and safety.

4. Direct Metal Laser Sintering (DMLS)

DMLS, trademarked by EOS GmbH, a German additive manufacturing company, operates similarly to SLM. Despite the term "sintering" being used, it achieves full melting. TWI holds the distinction of being the first UK entity certified to manufacture using this technology.

Metal Binder Jetting

Binder jetting, much like laser sintering, is not limited to metal materials; it can also handle sand, ceramic, and full-color objects. Unlike other traditional metal printing methods, binder jetting operates at room temperature, eliminating warping and the need for supports. Consequently, binder jetting machines can be larger, allowing objects to be stacked within the build chamber. This makes it a preferred choice for small batch production runs and on-demand replacement parts. In binder jetting, particles are bonded with an adhesive deposited by an inkjet, while material jetting uses a UV-cured polymer matrix. Though they have differences, they share similar pros and cons, like the need to account for shrinkage and control the sintering process precisely.

Metal Binder Jetting Pros:

- Large build volume

- Objects don't require attachment to a build plate, allowing for nesting and optimal use of space

- Minimal geometry restrictions as supports are typically unnecessary

- Capable of producing larger parts without warping

- Fast printing speed

- Lower cost compared to powder bed fusion metal printing

Metal Binder Jetting Cons:

- Parts require time-consuming debinding and furnace sintering after printing

- High initial investment in machines and materials

- Higher porosity compared to powder bed fusion, resulting in inferior mechanical properties

- Limited material selection

Metal Material Extrusion

Extrusion-based metal printing, designed for cost-effectiveness and accessibility, has seen widespread adoption among small to medium businesses, design studios, workshops, and small manufacturers. They utilize these machines for design iterations, creating tools, and running small production batches. A recent advancement includes metal filaments compatible with most desktop FDM 3D printers, democratizing metal printing for a broader audience. This technique involves heating and extruding metal-based filaments through a heated nozzle. Example of this method are Metal Fused Filament Fabrication (Metal FFF) and Metal Fused Deposition Modeling (Metal FDM).

Metal extrusion offers several advantages in metal 3D printing. Firstly, it's the most affordable method available, making it accessible to a wide range of users. Secondly, it enables the creation of functional prototypes, allowing for testing and validation of designs. Additionally, metal extrusion is easy and safe to operate, requiring minimal specialized training.

However, there are drawbacks to consider. Parts produced through metal extrusion must undergo the same debinding and sintering process as those from binder jetting, adding time and cost to the production process. Moreover, there are more restrictions on geometry, and supports are often necessary to prevent warping during printing. The resulting parts have high porosity and do not achieve the same mechanical properties as forged metals. Additionally, they are less dense compared to parts produced using powder bed fusion or directed energy deposition. Lastly, metal extrusion tends to be less accurate due to shrinkage in the furnace during post-processing.

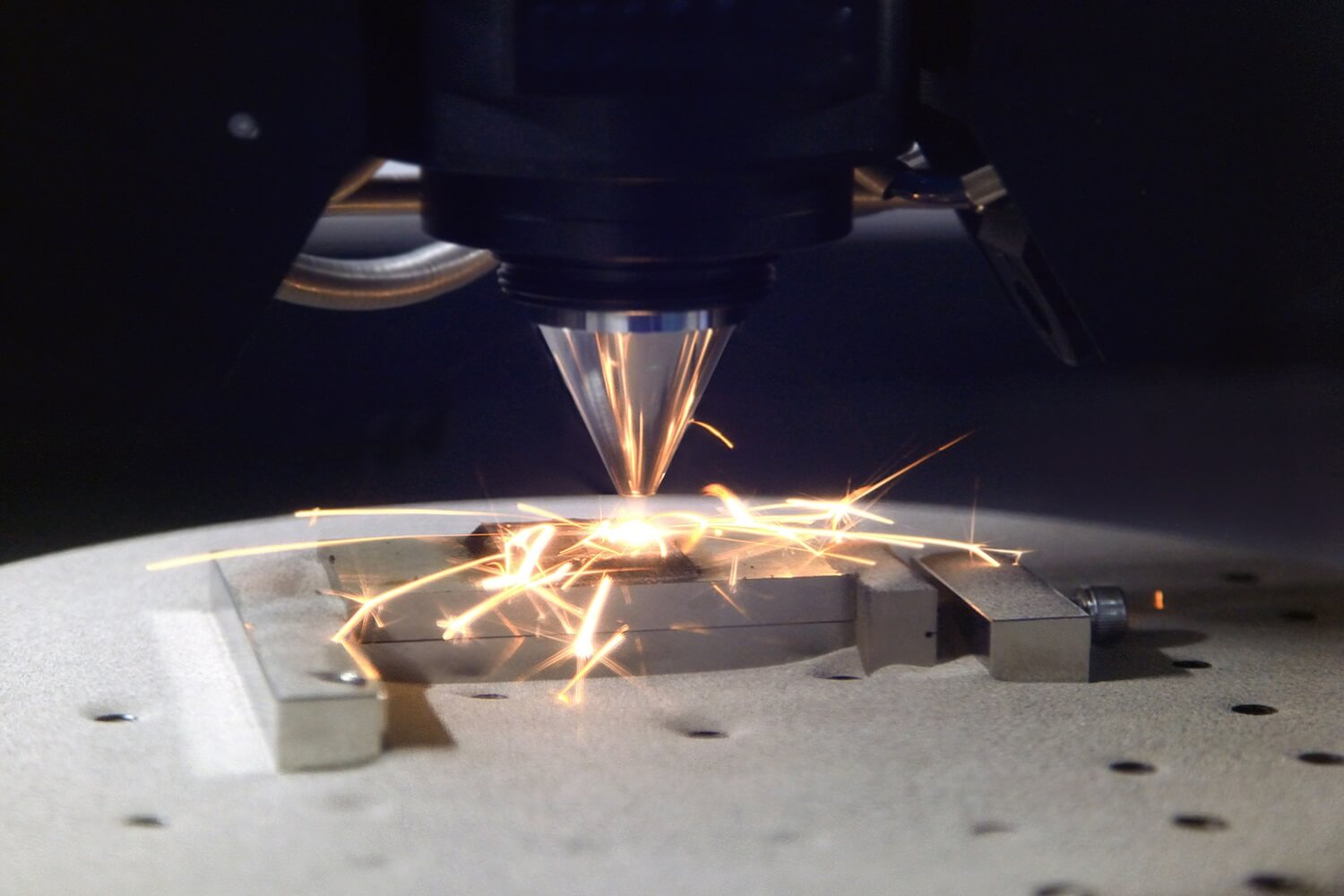

Directed Energy Deposition

DED (Directed Energy Deposition) is a metal 3D printing method that uses a focused energy beam, like a laser or electron beam, to create parts. It works by melting and depositing metal powder or wire onto a surface, building up layers to form the desired shape. Unlike other methods, DED fuses metal as it deposits, allowing for simultaneous deposition and fusion. A nozzle feeds material into the energy beam, which melts and deposits it onto the workpiece. Once a layer is done, the build table moves down, and the process repeats. After printing, parts may need post-processing for surface finishing.

How Does Directed Energy Deposition Work?

Directed Energy Deposition (DED) starts with designing a 3D model using CAD software, which is then sliced into layers. These layers guide the deposition process to build the final part.

DED involves melting material and depositing it onto a surface, where it solidifies to form a structure. Machines use a nozzle mounted on a multi-axis arm to precisely deposit material in various directions. The process typically occurs in a controlled environment with reduced oxygen levels to prevent oxidation. Material, either powder or wire, is melted by a heat source as it's deposited onto the surface layer by layer. Each layer solidifies quickly, with cooling rates of 1000-5000 °C per second, affecting the final grain structure. Parts are typically stationary during deposition, but a moving platform can also be used.

Exploring the Diverse Applications of Metal 3D Printing

-

Tool Components and Finished Parts: Metal 3D printing revolutionizes the production of tool components and finished parts across industries like aerospace, automotive, and marine by offering unparalleled precision and efficiency.

-

Medical Implants: Metal 3D printing enables the fabrication of intricate medical implants, including dental implants, leveraging its capacity to craft customized shapes and complex geometries for enhanced patient outcomes.

-

Aerospace Components: Metal 3D printing plays a vital role in crafting aircraft components like engine parts and structural elements, contributing to weight reduction and cost savings while maintaining superior performance standards.

-

Jewelry Design: Metal 3D printing opens new horizons in jewelry design, facilitating the creation of intricate pieces with precious metals like gold, silver, and bronze, bringing innovation and uniqueness to the industry.

-

Workholding and Alignment Tools: Metal 3D printing empowers the production of robust workholding and alignment tools, such as brazing fixtures, renowned for their strength and heat-resistant properties, enhancing manufacturing processes across various sectors.

Summary

In conclusion, metal 3D printing offers a wide array of innovative techniques, each with its own distinct advantages and applications across various industries. From the precision of Powder Bed Fusion to the versatility of Binder Jetting and the cost-effectiveness of Metal Material Extrusion, these methods have truly revolutionized manufacturing processes. Directed Energy Deposition further expands the possibilities with its unique capabilities.

With applications ranging from aerospace components to medical implants and jewelry design, metal 3D printing continues to transform industries worldwide, providing unmatched precision, efficiency, and customization. As technology advances and accessibility improves, the potential for metal additive manufacturing to shape the future of production remains vast and promising.