Discover the future of manufacturing with our guide to metal 3D printing. Transform industries with precision, customization, and efficiency in aerospace, automotive, and healthcare.

Exploring Metal 3D Printing: An Ultimate Guide for Industries

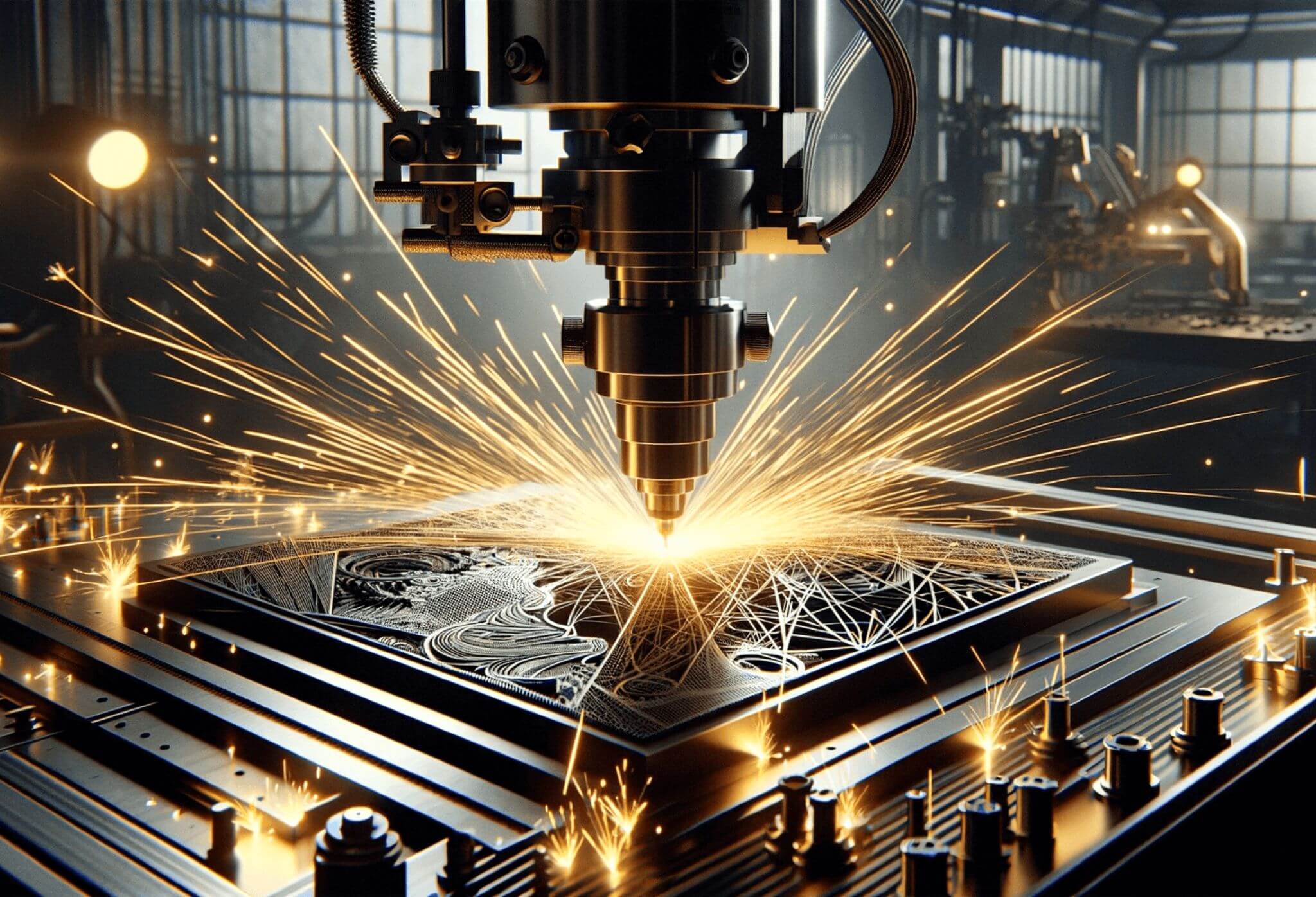

Metal 3D printing, also known as additive manufacturing, has revolutionized various industries by enabling the creation of complex and customized metal parts. This article serves as an ultimate guide, exploring the principles, processes, applications, benefits, and limitations of metal 3D printing.

What is Metal 3D Printing and How Does it Work?

Characteristics of Metal 3D Printing

Metal 3D printers have set parameters, including layer height and build size. The materials used are recyclable, with minimal wastage. Parts exhibit almost isotropic properties, high strength, and hardness. Considerations such as layer adhesion, support structures, and part orientation impact the final product's quality.

Here are the main characteristics of metal 3D printing:

1. Complex Geometries

Enables the creation of intricate and complex shapes that traditional manufacturing methods cannot achieve easily.

2. High Precision

Allows for precise control over the printing process, resulting in accurate and detailed final products.

3. Customization

Facilitates customization and personalized designs according to specific needs and requirements.

4. Material Variety

Supports various metal materials, including stainless steel, titanium, aluminum, and nickel alloys, offering a wide range of material properties.

5. Reduced Waste

Reduces material wastage compared to subtractive manufacturing methods due to an additive layer-by-layer approach.

6. Rapid Prototyping

Speeds up the prototyping phase, allowing for faster iterations and product development.ABS possesses robust mechanical properties, making it suitable for creating durable prototypes and end-use parts. Its flexibility allows for intricate designs without compromising strength, making it a preferred choice in various industries.

7. Strength and Durability

Provides strong and durable end products suitable for functional and load-bearing applications.

8. Post-Processing Requirements

Often requires additional post-processing steps like heat treatment or surface finishing to achieve desired material properties or surface quality.

9. Cost and Time Efficiency

While the technology advances, initial costs can still be high, but it can save time and costs in complex part production and small batch manufacturing.

10. Industry Applications

Used in aerospace, automotive, healthcare, and other industries where high-performance metal parts are necessary.

Metal 3D Printing Process

The process begins with filling the build chamber with inert gas to prevent oxidation. A thin layer of metal powder is spread, and a laser scans the cross-section of the component, melting the powder particles. The build platform descends, and the process repeats until the part is complete. Support structures, important for preventing warping, are also created.

When it comes to 3D printing materials, SLM and DMLS support various metals and alloys, such as aluminum, stainless steel, titanium, and cobalt chrome. Precious metals like gold and platinum find applications in jewelry making.

Applications of 3D Metal Printing

1# Tooling and Industrial Applications

Metal 3D printing serves industrial needs by fabricating custom tooling, molds, and machine components. It enables quick iterations in tool development and customization for specific manufacturing processes, improving efficiency and reducing downtime.

2# Healthcare Sector

In healthcare, 3D metal printing is revolutionizing the production of patient-specific implants, prosthetics, and surgical tools. Customized implants tailored to individual patients' anatomies improve treatment outcomes, while the technology allows for intricate and precise medical instrument fabrication.

3# Energy Sector

In energy production, especially in renewable energy, 3D metal printing contributes to the manufacturing of efficient components for wind turbines, solar panels, and power generation equipment. Complex, optimized designs help enhance energy production and equipment durability.

4# Automotive Manufacturing

The automotive industry utilizes metal 3D printing for rapid prototyping, tooling, and producing lightweight parts for vehicles. Components like engine parts, brackets, and customized parts for racing cars benefit from the technology's ability to create complex structures with high strength.

5# Aerospace Industry

Metal 3D printing finds extensive use in aerospace for producing lightweight, high-strength components like turbine blades, fuel nozzles, and structural parts. Its ability to create complex geometries and optimize designs contributes to enhanced performance and fuel efficiency in aircraft.

The Benefits of 3D Metal Printing

1. Customization and Prototyping

The technology enables customization at scale, allowing for tailored components without incurring additional costs or time. It also facilitates rapid prototyping, speeding up the product development cycle by quickly iterating designs and testing functionalities.

2. Design Freedom and Complexity

One significant benefit of 3D metal printing lies in its ability to produce complex geometries and intricate designs that traditional manufacturing methods struggle to achieve. This opens avenues for innovation, allowing engineers to design parts with optimized shapes and functionalities.

3. Material Versatility and Performance

Metal 3D printing supports various materials, including titanium, stainless steel, aluminum, and nickel alloys, each with distinct properties. This versatility allows for parts with specific characteristics like high strength, durability, or heat resistance, ideal for diverse industry applications.

4. Waste Reduction and Sustainability

Compared to traditional subtractive manufacturing methods, 3D metal printing significantly reduces material wastage. The additive manufacturing approach builds objects layer by layer, minimizing excess material use, leading to more sustainable production processes.

The Limitations of 3D Metal Printing

1. Post-Processing Requirements

One limitation involves post-processing needs. Printed metal parts often require additional steps like heat treatment or surface finishing to achieve desired material properties or surface qualities. These procedures can add time and cost to the production process.

2. High Initial Investment

The initial cost of 3D metal printing equipment and materials can be prohibitive for some businesses. While long-term savings may occur in certain scenarios, the upfront investment can pose a challenge for smaller enterprises or startups. Therefore, many companies are looking for reliable 3D printing service providers that have high-tech metal 3D printers in Malaysia to meet their 3D printing requirements.

3. Production Speed and Scale

Although 3D metal printing is advantageous for rapid prototyping, it might not match the speed of traditional mass production methods. Manufacturing larger quantities of parts using this technology can be time-consuming, limiting its scalability for high-volume production.

All in All

Metal 3D printing stands at the forefront of manufacturing technology, offering unparalleled design flexibility, customization, and efficiency. While it presents certain challenges, such as in terms of production speed and energy consumption, its advantages far outweigh the limitations, making it a transformative force in various industries.