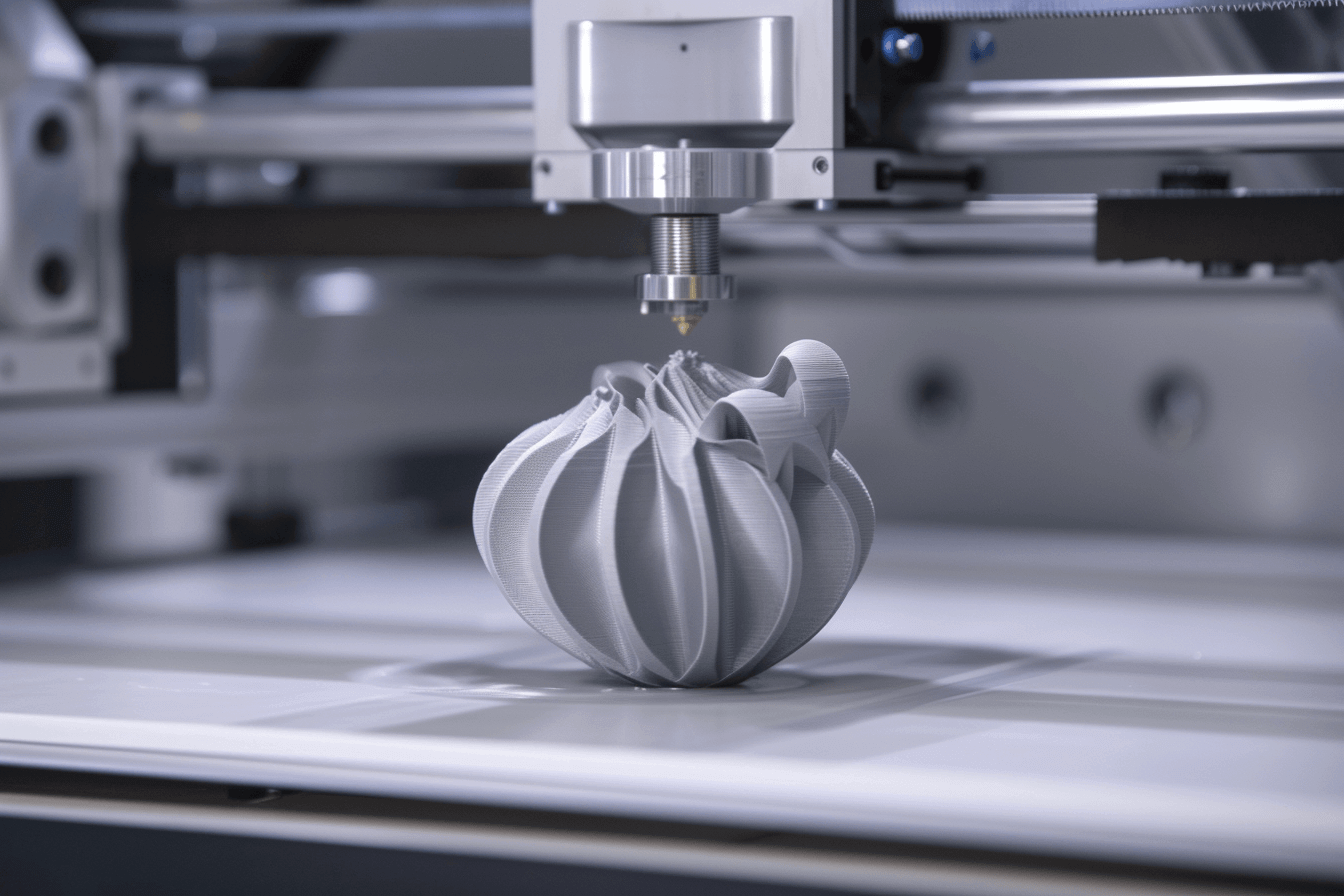

Discover how 3D printing revolutionizes rapid prototyping, slashing production time and costs. Swift iterations drive faster design validation, market entry, and competitive edge for businesses.

Leveraging 3D Printing for Rapid Prototyping & Product Development

Years ago, making prototypes by hand was slow and difficult. In the 1980s and 1990s, new methods like stereolithography and laser sintering made it faster but the high cost involved remained an issue. In the 2000s, the industry started using computer programs (CAD) to make digital models.

Today, the advent of 3D printing has empowered businesses across industries to reshape their prototyping processes, accelerating innovation, reducing production costs, and bringing groundbreaking products to market faster than ever before.

The 3D Printing Revolution

The advent of 3D printing, also known as additive manufacturing, has marked a significant disruption in traditional prototyping and product development. Unlike subtractive manufacturing methods, which involve cutting and shaping materials, 3D printing builds objects layer by layer from digital designs. This fundamental shift brings several benefits to the world of product development.

1. Speed and Cost-Effectiveness

One of the key advantages of 3D printing is its speed. It enables rapid prototyping, drastically reducing the time it takes to turn a concept into a physical object. Designers and engineers can now create prototypes in a matter of hours or days, as opposed to weeks or months with traditional methods. Additionally, 3D printing is cost-effective, eliminating the need for expensive molds, tooling, and skilled labor, making it accessible, especially for small and medium-sized businesses.

2. Iterative Design and Customization

The ease of making design modifications in a digital file translates to swift iterations in the physical prototype. Teams can quickly test and refine their ideas without incurring substantial additional costs. Furthermore, 3D printing can produce intricate and complex geometries that are challenging or impossible to achieve with traditional manufacturing methods, opening up new possibilities for innovative product designs. This customization extends to the consumer level, allowing businesses to produce personalized and tailor-made items, meeting specific needs and preferences.

3. Reduced Material Waste and Environmental Impact

Traditional manufacturing methods often produce significant material waste. In contrast, 3D printing is additive, creating objects layer by layer, minimizing waste and environmental impact. This not only aligns with eco-friendly production methods but also contributes to cost reduction as businesses spend less on raw materials.

The Significance of 3D Printing in Product Design

Prototyping Agility and Competitive Advantage

The integration of 3D printing into the product development process has brought about a fundamental shift in how businesses approach innovation. Prototyping becomes a speedy process, allowing teams to quickly create multiple iterations of a design, test them, gather feedback, and refine their concepts until they achieve the desired outcome. This agile approach, coupled with the reduction of risk through rapid prototyping, boost a culture of innovation within organizations.

Companies that leverage 3D printing for rapid prototyping gain a competitive edge by being able to respond swiftly to market changes and customer demands. This competitive advantage is rooted in the ability to bring products to market faster and more efficiently than competitors relying on traditional prototyping methods.

Accelerated Prototyping

Rapid Turnaround and Iterative Development

Traditionally, creating physical prototypes was time-consuming and resource-intensive. Designers and engineers had to rely on various methods, such as CNC machining or manual modeling, which often required significant lead times and cost expenditures. 3D printing has transformed this by offering unparalleled speed and efficiency.

With 3D printing, the time required to go from a digital design to a physical prototype is dramatically reduced. Prototypes can often be produced within hours or days, as opposed to the weeks or months it may take with traditional methods. The speed of 3D printing encourages iterative design and testing, allowing designers to quickly generate multiple iterations of a prototype, experiment with different concepts, and refine their designs in a fraction of the time.

Functional Prototypes and Faster Testing

The acceleration of prototyping through 3D printing brings several advantages in terms of testing and design refinement. Functional prototypes produced via 3D printing allow for early validation of design concepts, enabling the identification and addressing of potential issues at a stage where changes are less costly and time-consuming.

3D-printed prototypes can simulate real-world conditions, helping engineers and designers assess how a product behaves in its intended environment. This is particularly valuable for products with complex interactions or performance requirements. The cost savings achieved through rapid prototyping with 3D printing also contribute to enhanced collaboration within cross-functional teams, as engineers, designers, and stakeholders can work together more effectively to refine product designs and make informed decisions.

Cost Reduction Effect of 3D Printing

One of the key advantages of 3D printing in product development is its ability to significantly reduce production costs. Traditional manufacturing processes often generate substantial material waste, which has environmental and cost implications. In contrast, 3D printing minimizes waste by utilizing materials with high efficiency and eliminating the need for extensive tooling.

The minimal material waste produced by 3D printing contributes to a greener and more sustainable manufacturing process, aligning with the growing demand for eco-friendly production methods. The technology also eliminates or significantly reduces the need for expensive tooling, leading to substantial cost reductions. Design flexibility is enhanced, allowing for the production of complex geometries and intricate designs without the constraints imposed by traditional tooling.

Industry Applications: Automotive, Consumer Electronics, Fashion

Automotive

In the automotive sector, 3D printing has been harnessed to produce lightweight components, enhance vehicle performance, and accelerate the production of concept cars. Weight reduction is critical for improving vehicle fuel efficiency and performance, and 3D printing allows manufacturers to design and produce lightweight components that maintain structural integrity. The technology also expedites the development of concept cars and prototypes, enabling automotive companies to quickly produce and test new designs, saving both time and money in the product development process.

Consumer Electronics

The consumer electronics industry has been quick to embrace 3D printing technology as a means to innovate and create cutting-edge devices with streamlined design and improved functionality. Speed to market is critical in this industry, and 3D printing allows manufacturers to rapidly prototype and iterate on new designs, reducing the time required to develop new products. This agility enables companies to stay ahead of the competition and respond swiftly to changing consumer demands.

Fashion and Wearables

In the fashion and wearables industry, 3D printing has revolutionized the creative process and product customization. Fashion designers and wearable technology creators leverage 3D printing to craft unique, customizable designs that were previously challenging or impossible to create with traditional manufacturing methods. This technology allows for complex patterns, textures, and shapes that can be tailored to individual tastes. Furthermore, 3D printing in fashion promotes sustainability by minimizing material waste, aligning with the growing demand for eco-friendly and waste-reducing practices in the fashion industry.

Final Takeaways

The impact of 3D printing on innovation, cost reduction, and faster time-to-market has revolutionized many industries. With advancements in technology and more flexible materials, 3D printing will continue to revolutionize product development, bringing about even more significant changes in industries. All in all, the future holds even more exciting possibilities for 3D printing across a wide range of applications.