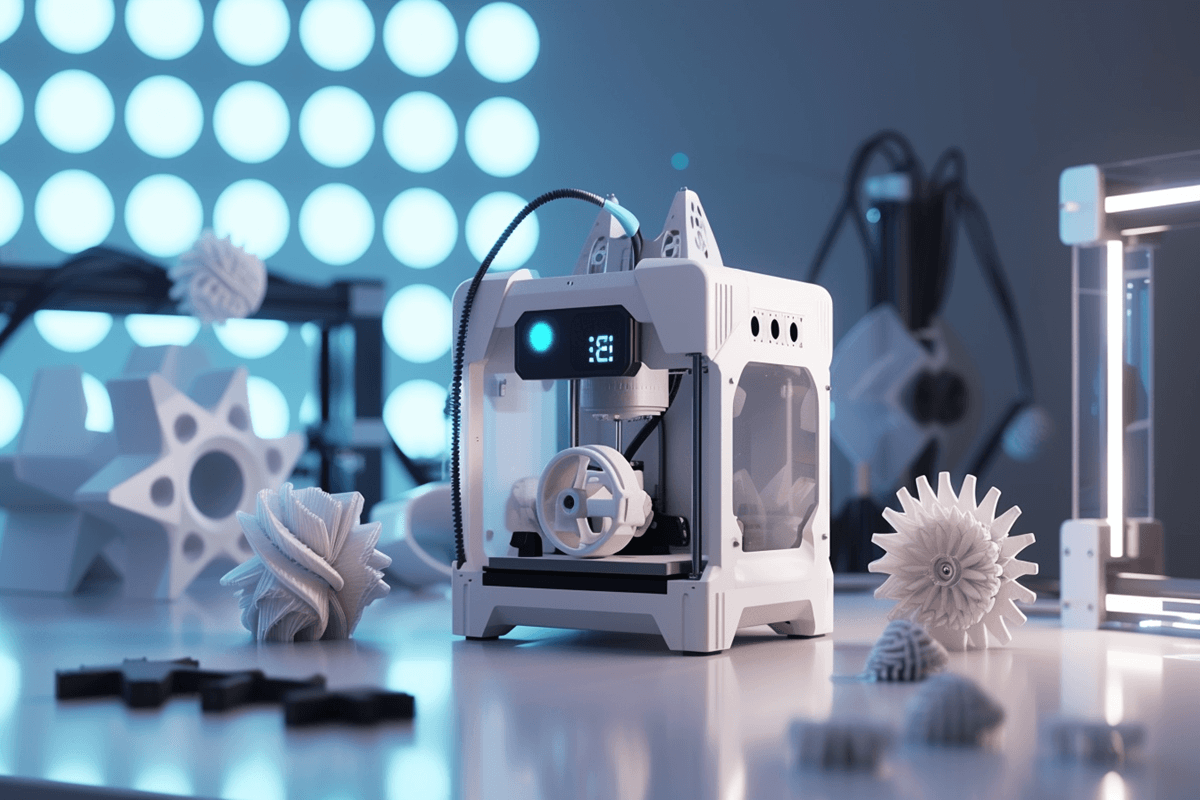

Discover the significant advantages of using 3D printing for prototyping. This concise list outlines the key benefits, including speed, cost-effectiveness, design flexibility, and more.

3D printing has revolutionized product development, offering a swift, cost-effective, and precise alternative to traditional prototyping methods. This advanced technology enhances the appeal of prototypes, impressing stakeholders while allowing rapid iteration and testing of designs. The guide offers insights into selecting appropriate materials, deciding whether to invest in a personal printer or utilize on-demand services, and optimizing the 3D printing process to expedite product conceptualization and market entry.

Understanding Prototyping in 3D Printing Manufacturing

Prototyping in 3D printing manufacturing is the initial stage of product development where a physical model or prototype is created using a 3D printer. This process allows designers, engineers, and manufacturers to visualize, test, and refine their product concepts before full-scale production. It serves as a crucial step in the product development cycle, facilitating design validation, functional testing, and the identification of potential improvements or modifications.

During 3D printing prototyping, a computer-aided design (CAD) file is used to build a three-dimensional object layer by layer. This technology enables the rapid and cost-effective production of prototypes with complex geometries and intricate details. Prototypes can be made from various materials, including plastics, metals, ceramics, and even composites, depending on the intended application.

The benefits of 3D printing prototyping include reducing development time, minimizing design flaws, and lowering overall production costs. It allows for the validation of product features, ergonomics, and functionality early in the design process, helping businesses bring high-quality products to market more efficiently.

Why use 3D Print for Prototyping?

3D printing has revolutionized the way prototypes are developed and tested in various industries. Its ability to quickly and cost-effectively produce physical models has made it an invaluable tool for designers, engineers, and manufacturers. In this detailed explanation, we will explore the compelling reasons why 3D printing is the preferred choice for prototyping, delving into its benefits and advantages in depth. These key points highlight how 3D printing expedites the design process, saves costs, enables complex geometries, and facilitates functional testing, among other critical aspects.

1. Rapid Prototyping:

Rapid prototyping is a fundamental application of 3D printing technology that plays a pivotal role in product development and innovation. It refers to the swift and iterative creation of physical prototypes or models using 3D printing techniques. This process enables designers, engineers, and manufacturers to quickly transform their digital designs into tangible, physical objects for testing, evaluation, and validation.

Key aspects of rapid prototyping in 3D printing include:

-

Speed: Traditional methods of prototyping, such as CNC machining or injection molding, can be time-consuming and expensive. 3D printing allows for the rapid production of prototypes, reducing lead times significantly.

-

Iteration: Rapid prototyping facilitates the creation of multiple iterations or versions of a design in a short period. This iterative approach is essential for refining and improving product designs.

-

Cost-Efficiency: By eliminating the need for custom tooling and molds, 3D printing can be a cost-effective solution for creating prototypes, especially when compared to traditional manufacturing methods.

-

Customization: 3D printing enables the easy customization of prototypes to meet specific design requirements or address unique challenges.

-

Complex Geometries: 3D printing can produce complex and intricate geometries that are challenging or impossible to achieve with traditional manufacturing methods.

-

Functional Testing: Rapid prototypes can be used for functional testing and validation, allowing engineers to assess the performance of a design before committing to full-scale production.

-

Reduced Waste: Additive manufacturing generates minimal waste compared to subtractive manufacturing methods, making it a more sustainable option.

3D printing revolutionizes product development by enabling the rapid and cost-effective creation of physical prototypes. This accelerates the development cycle, facilitating quick iterations and testing of multiple product versions. It has transformed how industries like aerospace, automotive, healthcare, and consumer goods design and bring new products to market, fostering innovation and agility in the process.

2. Cost-Effective Iteration:

Using 3D printing for prototyping offers several advantages, with cost-effective iteration being a key benefit. Traditional prototyping methods often involve expensive and time-consuming processes, such as CNC machining or injection molding, which can lead to high upfront costs and lengthy lead times for design changes.

In contrast, 3D printing allows for rapid and cost-effective iteration. Design modifications can be made digitally, and new prototypes can be produced quickly without the need for costly tooling or molds. This means that designers and engineers can test and refine their ideas more frequently, reducing development costs associated with tooling changes.

Furthermore, 3D printing materials are available in a wide range of options, including affordable ones like PLA and PETG. This variety enables cost-effective testing of different materials and design variations to achieve optimal results.

3D printing is a compelling choice for prototyping due to its ability to rapidly and inexpensively iterate on designs, resulting in significant time and cost savings. Unlike traditional prototyping methods that often require expensive molds or tooling, 3D printing eliminates the need for such costly setups. This is particularly advantageous when multiple design iterations are necessary, as it reduces upfront expenses and accelerates the development process. Ultimately, 3D printing offers a cost-effective solution for creating and refining prototypes, making it a valuable tool in the product development journey.

3. Complex Geometries:

One of the compelling reasons to use 3D printing for prototyping is its ability to handle complex geometries with ease. Traditional manufacturing methods may struggle to produce intricate and unconventional designs, whereas 3D printing excels in this regard.

The layer-by-layer additive manufacturing process of 3D printing allows for the creation of complex and intricate structures that would be challenging or impossible to achieve through conventional means. This capability is particularly beneficial for industries like aerospace, automotive, and healthcare, where intricate and custom designs are often required.

By embracing 3D printing for prototyping, designers and engineers can unleash their creativity and explore innovative shapes and configurations without limitations. This results in the development of more advanced and efficient products, ultimately enhancing competitiveness in the market. The ability to prototype complex geometries efficiently is a key advantage of 3D printing in the product development process.

4. Customization:

The ability to customize prototypes extensively is a key reason for using 3D printing. Traditional manufacturing often makes identical parts, limiting design flexibility. In contrast, 3D printing allows quick changes to prototypes, like resizing or adding features, without costly adjustments. This customization is crucial in healthcare for personalized medical items and in making unique consumer products. It empowers designers to create prototypes that match specific needs, making 3D printing a valuable tool for customized solutions.

With 3D printing, it's easy to customize prototypes for specific needs or individual clients. This flexibility is particularly useful in industries like healthcare, where personalized medical devices or implants are required.

5. Functional Prototypes:

3D printing is chosen for prototyping because it allows for the creation of functional prototypes. These prototypes aren't just for show; they can actually perform like the final product. This is important for testing and validating the design. Whether it's a mechanical part, an electronic component, or a complex assembly, 3D printing can produce prototypes that work as intended. This functionality is a major advantage because it helps identify and fix issues early in the development process, saving time and resources.

3D printers can produce functional prototypes that closely mimic the final product's form, fit, and functionality. This allows for rigorous testing and validation of the design before committing to full-scale production.

6. Reduced Material Waste:

Choosing 3D printing for prototyping is a sustainable option due to reduced material waste. Unlike traditional methods that may involve carving or cutting excess material, 3D printing builds prototypes layer by layer, using only the necessary amount of material. This efficient process minimizes waste, saving resources and costs, while also being environmentally friendly by producing less waste.

Traditional subtractive manufacturing processes can generate significant material waste. In contrast, 3D printing is an additive process, which means it only uses the material necessary to build the object, minimizing waste.

7. On-Demand Production:

3D printing is valuable for prototyping because it enables on-demand production. Instead of waiting for molds or tools to be created, 3D printing allows you to quickly produce prototypes whenever you need them. This on-demand capability streamlines the product development process, making it more efficient and responsive to changing requirements.

Prototypes can be 3D printed on-demand, reducing the need for large inventories of pre-made parts. This is particularly beneficial for companies embracing just-in-time manufacturing practices.

8. Design Validation:

The significance of 3D printing in prototyping lies in its ability to validate designs. Through 3D printing, you can swiftly produce physical prototypes to examine and confirm your product's design. This ensures that any design problems or concerns can be identified and addressed early in the development phase, leading to time and cost savings. It's akin to having a tangible model to guarantee that your product will perform as planned before proceeding with full-scale production.

Physical prototypes created with 3D printing enable designers and engineers to validate their concepts and make necessary adjustments early in the design phase. This reduces the risk of costly design flaws being discovered late in the production process.

9. Material Variety:

Using 3D printing for prototyping is advantageous because it offers a wide range of materials to choose from. This means you can select the material that best suits your specific project needs, whether it's plastic, metal, resin, or even food-grade materials for unique applications like custom chocolates. Having access to diverse materials allows for greater flexibility and creativity in prototyping.

3D printing supports a wide range of materials, from plastics and metals to ceramics and composites. This versatility allows for the selection of materials that closely match the properties of the final product.

10. Reduced Lead Times:

One of the key benefits of using 3D printing for prototyping is the significant reduction in lead times. Traditional manufacturing methods often involve time-consuming processes, such as tooling and mold creation, which can result in long wait times before prototypes are ready.

In contrast, 3D printing is a rapid and on-demand process. Once a 3D design file is prepared, the printer can start creating the prototype immediately. This speed accelerates the product development cycle, enabling designers and engineers to iterate and test multiple versions of a product in a much shorter timeframe.

Reduced lead times are particularly advantageous in industries where time-to-market is critical, such as electronics, automotive, and consumer goods. With 3D printing, businesses can bring their concepts to life faster, stay ahead of competitors, and respond quickly to changing market demands. This agility in prototyping can ultimately lead to more successful and competitive products.

3D printing can significantly reduce lead times, especially for small-batch or one-off prototypes. This agility is vital in industries with rapidly changing market demands.

11. Accessibility:

3D printing has made prototyping more accessible than ever before. In the past, creating prototypes often required specialized facilities and equipment, making it challenging for small businesses or individuals to participate in the product development process.

With the advent of desktop 3D printers and online 3D printing services, anyone can access prototyping capabilities. Desktop 3D printers are user-friendly and affordable, allowing designers, engineers, and hobbyists to create prototypes in their own workspace. Online services offer a wide range of materials and technologies, making it easy to upload a design and receive a professionally printed prototype.

This accessibility democratizes innovation, enabling startups and individuals to bring their ideas to life without the need for significant investments in manufacturing equipment. It fosters a culture of creativity and innovation, where anyone with a concept can explore, test, and refine their ideas through prototyping.

3D printing technology has become more accessible and affordable, enabling smaller businesses and entrepreneurs to leverage its benefits for prototyping without substantial upfront investments.

Conclusion

In summary, 3d printing has transformed prototyping by offering rapid, cost-effective, and customizable solutions. Its benefits include rapid prototyping, cost-effective iteration, handling complex geometries, customization, functional prototypes, reduced material waste, on-demand production, simplified design validation, material variety, and reduced lead times. Additionally, its accessibility has democratized innovation, making it an indispensable tool for designers, engineers, and small businesses alike.