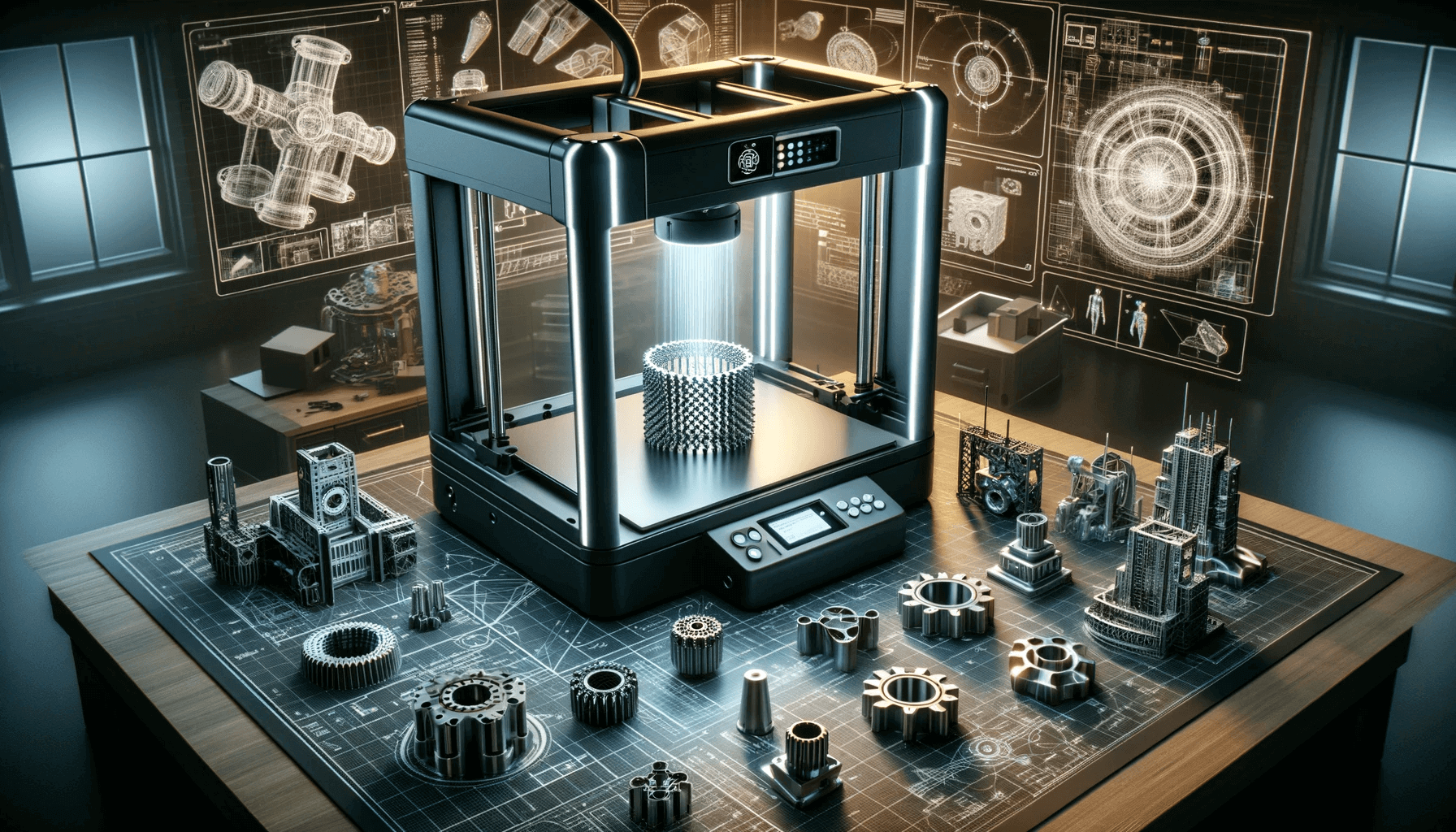

SLA 3D printing offers precision and cost-efficient prototyping. It's reshaping manufacturing by unlocking innovation, customization, and efficiency as industries adopt this transformative technology.

What is SLA 3D Printing: Transforming Industrial Manufacturing

Industrial manufacturing is constantly evolving and cutting-edge technologies play an important role in this transformation. Stereolithography (SLA) 3D printing has emerged as a revolutionary process that has significantly impacted the industrial manufacturing sector.

In this comprehensive guide, we will explore the intricacies of SLA 3D printing, exploring its principles, applications, advantages, and how it is reshaping industrial manufacturing.

About Stereolithography 3D Printing

Stereolithography, commonly known as SLA 3D printing, is an additive manufacturing process that utilizes photopolymerization to create three-dimensional objects layer by layer. This process starts with a digital model that is sliced into thin layers. A vat of liquid resin, which hardens when exposed to ultraviolet (UV) light, is used to build these layers. The UV laser selectively solidifies the resin, forming a precise and detailed object.

SLA 3D printing is particularly well-suited for industrial manufacturing due to its ability to produce intricate designs with high accuracy and resolution. The technology has gained widespread acceptance across various industries, including automotive, aerospace, healthcare, and consumer goods.

Applications in Industrial Manufacturing

The versatility of SLA 3D printing makes it a game-changer in the industrial manufacturing sector. One of its primary applications lies in rapid prototyping. Engineers and designers can quickly iterate through designs, allowing for a more streamlined product development process. This rapid prototyping capability significantly reduces time-to-market for new products, an important factor in today's competitive manufacturing scenario.

Moreover, SLA 3D printing facilitates the production of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. This is particularly beneficial for industries requiring complex components, such as aerospace, where lightweight and precisely designed parts are necessary for optimal performance.

Advantages of SLA 3D Printing in Industrial Manufacturing

1. Cost-Efficiency in Prototyping

In the industrial manufacturing sector, prototyping is an important step in product development. SLA 3D printing stands out for its cost-efficiency in this regard. Traditional prototyping methods often involve expensive tooling and longer lead times. With SLA 3D printing, manufacturers can quickly and cost-effectively produce prototypes, enabling them to test and validate designs before committing to full-scale production.

2. Precision and Accuracy

The high precision and accuracy offered by SLA 3D printing make it an ideal choice for manufacturing components with tight tolerances. The technology's ability to produce complex details ensures that the final products meet the required specifications. This is particularly important in industries like medical manufacturing, where precision is important for producing implants and other medical devices.

3. Customization and Complexity

Industrial manufacturing often demands customization and the production of complex components. SLA 3D printing excels in meeting these requirements. Whether it's creating personalized medical implants or intricate aerospace components, the technology allows for the production of highly customized and complex designs that may be impractical or impossible with traditional manufacturing methods.

Challenges and Considerations

While SLA 3D printing offers numerous advantages, it is necessary to acknowledge some challenges and considerations associated with the technology in the industrial manufacturing sector. One notable consideration is the material selection. The range of available resins may not cover all industrial requirements, and manufacturers need to carefully evaluate the mechanical properties, durability, and chemical resistance of the chosen materials.

Additionally, post-processing steps, such as cleaning and curing, are integral to achieving the desired quality in SLA 3D-printed parts. Manufacturers must factor in these steps in their production workflow to ensure the final products meet industry standards.

Future Trends and Innovations

As technology continues to advance, the future of SLA 3D printing in the industrial manufacturing sector looks promising. Ongoing research and development are focused on enhancing material options, improving printing speed, and expanding the scale of production.

Innovations such as continuous liquid interface production (CLIP) and improvements in resin formulations are opening new possibilities for SLA 3D printing, further solidifying its role in shaping the future of industrial manufacturing.

Final Thoughts

The use of stereolithography (SLA) 3D printing serves as a transformative force in the industrial manufacturing sector. Its precision, versatility, and cost-efficiency make it a valuable tool for rapid prototyping and the production of complex components.

As industries continue to adopt and integrate SLA 3D printing into their workflows, the technology is poised to play an important role in shaping the future of industrial manufacturing. By adopting the capabilities of SLA 3D printing, manufacturers can unlock new possibilities for innovation, customization, and efficiency in their production processes.